You are here : Home | Expanded Metal Sheets

EXPANDED METAL :

TERMINOLOGY

STYLE DESIGNATION

A combination of numbers, letters, and abbreviations permitting proper specifications of dimension, Gauge, Style, and Weight.

In expanded metal products, The first number designates nominal dimension, Short way of design.

The second number completes the designation and may specify the gauge of metal, Weight per 100 square feet, or may have some other significance.

Grating products are designated by weight of finished product per square foot.

STANDARD EXPANDED METAL

Standard expanded metal as it comes from the press.

The strands and bonds are set at a uniform angle to the plane on the sheet.

This gives added strength and rigidity, as well as skid-resistant surface.

Standard expanded metal is abbreviated XM.

FLATTENED METAL

Flattened expanded metal is manufactured by passing the standard expanded sheet through a cold roll reducing mill.

Flattened expanded metal turns the strands and bonds down to provide a flattened surface, reducing the thickness (gauge) and elongating the pattern.

Thickness may vary plus or minus 10% from published dimensions.

GRATING

Grating is a standard expanded metal pattern produced from heavier gauge low carbon steel plates.

Strands and the openings of grating are considerably larger than other meshes.

It is ideal for use wherever a strong, durable, lightweight surface is needed.

Although used primarily for pedestrian traffic, grating can accommodate heavier loads if properly supported.

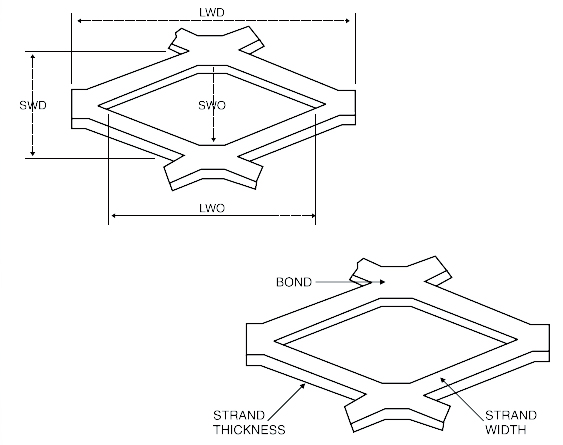

DESIGN SIZE : Actual dimensions SWD and LWD. Measured from a point to a corresponding point on the design shown.

SWD : Nominal dimension Short Way of Design

SWO : Short Way of Opening

LWD : Nominal dimension Long Way of Design

LWO : Long Way of Opening

STRANDS : The sides of the expanded metal design.

STRAND THICKNESS : Gauge thickness of metal expanded.

STRAND WIDTH : Amount of metal fed under dies to produce one strand.

BOND : The solid intersection of two strands.

SIDE SHEARING

The process of cutting a piece of expanded metal parallel to the long dimension of the diamond.

RANDOM SIDE SHEARING

: Side shearing is a cut made parallel to the LWD dimension of the sheet which usually leaves open diamonds.

BOND SIDE SHEARING : This cut is made along the length of the sheet on the center line of the bond over the specified width.

In most cases it is not practical to attempt to Bond Side Shear either regular or flattened expanded metal because of the camber.

END SHEARING :

END RANDOM SHEARING

: The process of shearing a piece of expanded metal to a specified length (LWD).

This cut normally leaves open diamonds at both ends but accomplishes close tolerance when both ends are sheared.

END BOND SHEARING : The process of shearing a piece of expanded metal to a specified length (LWD).

One end is cut on the Bond parallel to the SWD—the other end usually has open diamonds.

ORDERING PROCEDURE : When ordering Expanded Metals, give complete style specifications to avoid possible error.

Include style, standard orflattened, type of metal, and sheet dimensions.

SWD dimensions always given before LWD.

Drawings are exaggerated for illustrative purpose.