You are here : Home | Cable Trays

It is good to laying cable in cable tray , instead of pooling through pipe. In cable Tray wires can be seperated properly and air circulation is also there. any body Can manage properly wiring through cable tray. Is easy to extend wiring at the Time of future expansion also. If any wiring fault is there, it is easy to find out, if Wiring is done through cable tray.

Generally cable tray are being used in metal form like ms hot dip galvanized, pre Galvanized cable tray, ms painted cable tray, ms powder coated, aluminium cable Tray, stainless steel cable tray etc. 90 % industries are using hot dip galvanized Cable tray, as hot dip galvanized cable tray life is much more then, paintec cable Tray or powder coated cable tray.

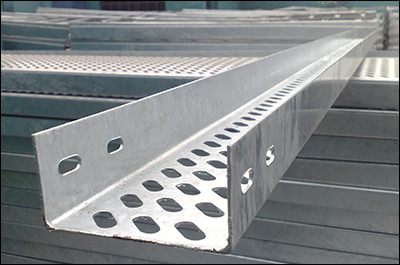

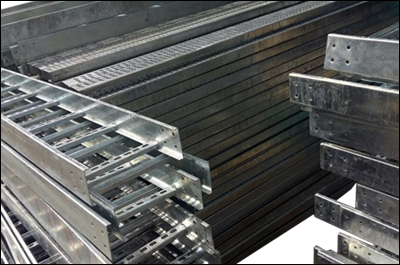

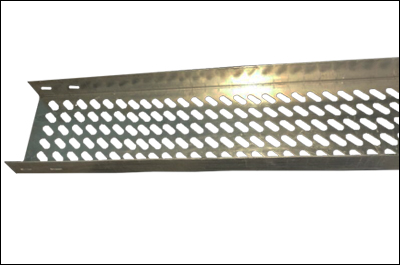

Mainly there is use of two types of cable tray, one is perforated type cable tray and second is ladder type cable tray. Perforated type cable tray is generally being Used in internal wiring purpose and ladder type is being used for out side wiring or for heavy cables. Now a days each any every industries are using cable tray for Wiring purpose, as Cable tray can be connect through coupler plates, it can be move horizontally, Vertically and in any direction through cable tray supporting system, cable tray Accessories. Cable tray can be of any size from 50 mm to 1500 mm or more then

That. In perforated type cable tray bottom is perforated so that air circulation is Easy and more. Cable tray height can be from 25 mm to 200 mm or more. Cabel tray

Thickness can be from 1 mm to 5 mm. For ladder type cable tray bottom is like Ladder and generaly used for heavy and out door cablings. Cable tray can be in Multy layer also.